Digital twins, as defined by the digital twin consortium, are a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. In practice, this can have a wide variety of interpretations. What does virtual mean? What counts as simulation? What counts as a digital twin or doesn’t?

The history of digital twins goes back as far as the 1970s with simulators used by NASA, progresses with the advent of CAD technology in the 1980s, and then the application of both in the aerospace and manufacturing industries in the 1990s and 2000s. Engineers would use a combination of simulation, 3D visualization, and real-time data to aid in the construction of highly complex machinery such as airplane engines. This technology was used for decades before the term “digital twin” appeared, which wasn’t until 2010.

Since then, digital twin technology has come to be understood to include all the previous technology plus a mix of the Internet of Things (IoT), artificial intelligence (AI), and cloud computing. Nowadays, digital twins are proving useful in a variety of fields — not just for building airplanes, but entire buildings and cities.

Digital twin technology is what has opened the door to address the problem that buildings account for 40% of global carbon emissions. But what type of digital twin is being used exactly? Is it the same type of digital twin that was used decades ago, or is it different now?

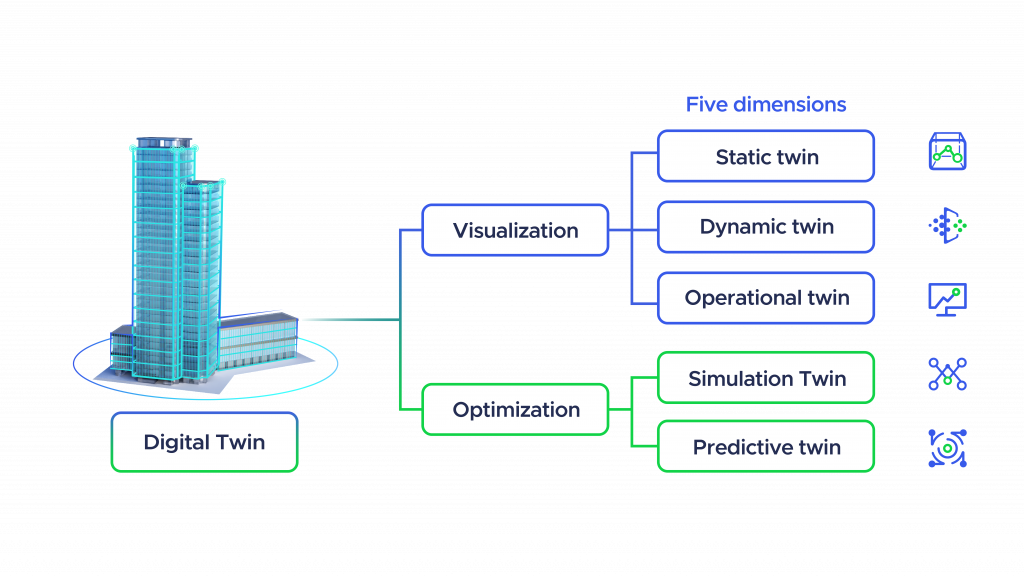

The best way to understand digital twins is on a scale of five dimensions ranging from simple to complex.

Digital twins in five dimensions

A useful way to understand digital twins is between two planes and five different dimensions of functionality. A digital twin in its simplest form is the digitalization and visualization of a physical asset in three dimensions: a static twin, a dynamic twin, and an operational twin. In its advanced form, it is a powerful engine of optimization in two more dimensions: simulation and prediction. As a twin becomes more advanced, users can benefit from improved support with decision-making and planning.

Visualization (layers 1-3)

Visualization is taking a physical object or abstract process and digitalizing it. All performance of an equipment or task can be represented in data – units of time, energy, output, etc. Digital twins can exist in up to three dimensions of visualization ranging from simple to complex.

Static twins

A static twin is a rudimentary digital twin. Static twins are created with data pulled from a real-life object at a specific time interval as designed. However, this data is still highly accurate and must be a 1-to-1 with reality. Even though static twins are “simple,” they can be visualized in a variety of manners using 3D BIM modeling, charts, and schematics. Static digital twins are also capable of simulation. However, this simulation is done without using real-time data and so leaves a

Although static twins are useful, they are not truly alive. The lack of several key functionalities holds the static twin from its true potential.

Dynamic twins

The next important dimension of a digital twin is the representation of its physical twin at the same point in time. The dynamic twin connects the two using real-time data collected by sensors and IT systems, such as IoT devices and data collection servers. Dynamic digital twins break down data silos between different systems and operations since they can communicate through this infrastructure.

Operational twins

Operational twins are where digital twins truly come alive. It goes beyond the dimension of time (as-is) to show how each piece of equipment and each process are performing. This builds on the analytical ability of the dynamic twin to connect with operations via automated alerts and work order systems to correct anomalies. This extends its usefulness and functionality beyond intelligence to include facility operators (technicians, engineers, etc.) at your site.

Most businesses can benefit immensely from the digitalization and visualization of their equipment, systems, and operations. These three dimensions of the digital twin, if implemented smartly, can lead to gains in efficiency and reduce wasted time, money, and energy.

However, the potential functionality of digital twins is even greater. By integrating more complex technology, visualization turns into optimization.

Optimization (layers 3-5)

Digital twins can tell us what might happen in the future. At their highest form, they can automatically optimize their real-life counterparts. These twins go beyond data and gain the capability to control and make decisions. The first step is simulation.

Real-time simulation twins

If things stay the same – what is the result? If we change this process or that piece of equipment – will that prove better or worse (decrease energy use, etc.)? Simulation twins can provide the answer.

Simulation twins integrate all known variables (layers 1-3) with digital simulation models that rely on physics to calculate how certain situations would affect these metrics in the future. It uses real-time data as input to simulate more accurately and precisely. For example: if our building turns off our air conditioning and lighting in unoccupied rooms at 6:30 pm each evening, how much energy/carbon will that reduce? Or, if we replace this chiller with a newer model, what boost in performance and efficiency can we expect – and for how long – before it diminishes due to use?

Simulation twins are highly valuable for decision-making support. Companies with ambitious plans to reduce energy use and carbon footprints would find that simulation twins remove the guesswork and complicated modeling because all information is contained inside a single model and platform.

As impressive as this is, there is still one more layer.

Predictive twin

The predictive twin does more than calculate what will happen; it automatically acts on decisions. The predictive twin uses AI and machine learning to see how equipment or systems might be affected by variables like weather or climate and implements optimization protocols in anticipation of them.

Predictive twins are the pinnacle of smart buildings. They can enable your site to reach a lifetime of optimized operations.

Digital twins have come a long way since their inception, and they can still appear in a variety of forms ranging across five dimensions of functionality. Each dimension of functionality is useful in different circumstances. When it comes to tackling the most important issues facing organizations today, digital twins that can optimize performance and processes are going to be the most powerful.

Akila has already used digital twins to optimize the operations and performance of clients’ properties ranging from a single site to an entire portfolio. We are aiming to develop the most advanced predictive twins for the built environment. By leveraging the five dimensions of digital twins, Akila empowers users to achieve alignment between productivity, profitability, and sustainability.