Preventative maintenance is the proactive approach to equipment maintenance, involving regular inspections, servicing, and repairs to prevent issues before they could occur, ultimately extending asset lifespan.

Akila’s new feature, launched on October 15th, enhances this approach by directly connecting automated alarms to maintenance work orders and inspections, ensuring faster responses and streamlining the asset management process.

By addressing potential problems before they occur and potentially leading to equipment breakdowns, preventative maintenance helps reduce costs, minimize downtime of equipment, and improve operational efficiency.

However, many maintenance systems lack real-time monitoring or don’t implement it well enough to allow for predictive alarms. Maintenance actions are too often delayed due to the disconnect between performance data and the actions needed to address issues, resulting in inefficiencies in the maintenance workflow.

This is where Akila’s latest feature steps in.

The Importance of Preventative Maintenance

In traditional maintenance processes, issues are often only addressed after an issue has arisen and the equipment has therefore failed. This way of working leads to emergency fixes and unplanned downtime, which can disrupt operations, not only for users but also for maintenance teams.

When equipment stops working it also implies costs as it implies downtime and a break in productivity. These costs are higher most of the time than if the equipment had been monitored closely and minor issues had been fixed earlier, leading to no or less downtime.

Preventative maintenance offers a major improvement by focusing on routine inspections and scheduled maintenance. By keeping equipment in optimal working condition, it minimizes unexpected failures and extends the life of assets, making them more reliable and efficient. It also helps ensure compliance with safety standards, further protecting both employees and equipment.

Despite the benefits, challenges in implementing preventative maintenance programs remain, especially because many systems don’t offer real-time monitoring or effective alarm setups. Even when alarms are present, performance data is often siloed from maintenance actions, leading to delays in response times. Without a direct connection between monitoring systems and the teams responsible for repairs, issues may escalate unnecessarily.

This is the gap Akila’s new feature seeks to fill, allowing maintenance teams to act quickly and decisively when alarms are triggered.

Akila’s New Feature: Connecting Alarms to Maintenance Work Orders

Akila’s new feature takes preventative maintenance to the next level by integrating alarm systems with work order creation. Whenever an issue is detected on equipment, action is taken by the system quickly and maintenance teams are informed. This highlight of any issue in real-time allows maintenance managers to assess the situation and quickly initiate the necessary actions.

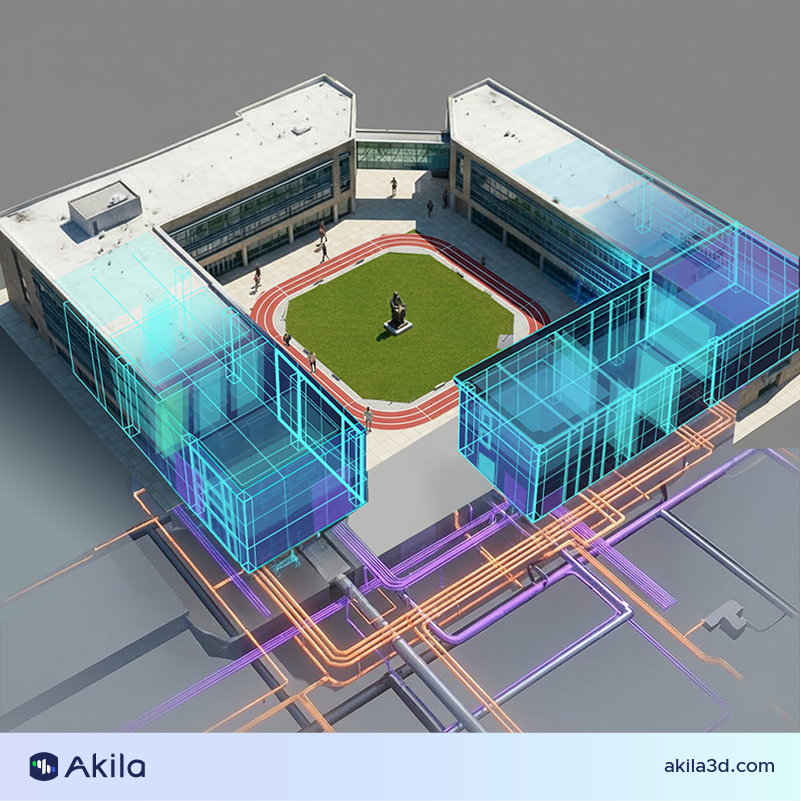

Here’s how it works: Akila’s platform continuously monitors equipment performance through digital twins. The system is able to detect any malfunction by analyzing the data sent from the sensors. If any malfunction or anomaly is identified, such as a performance anomaly or diminished output an alarm is triggered.

This alarm alerts managers to the issue, enabling them to create a work order that links the alarm directly to the necessary maintenance actions.

By highlighting potential problems as they arise, this system allows maintenance teams to address issues before they escalate into larger, more costly failures. The quick transition from detection to response ensures that no time is lost in addressing potential concerns.

Closing the Loop in Equipment Lifecycle Management

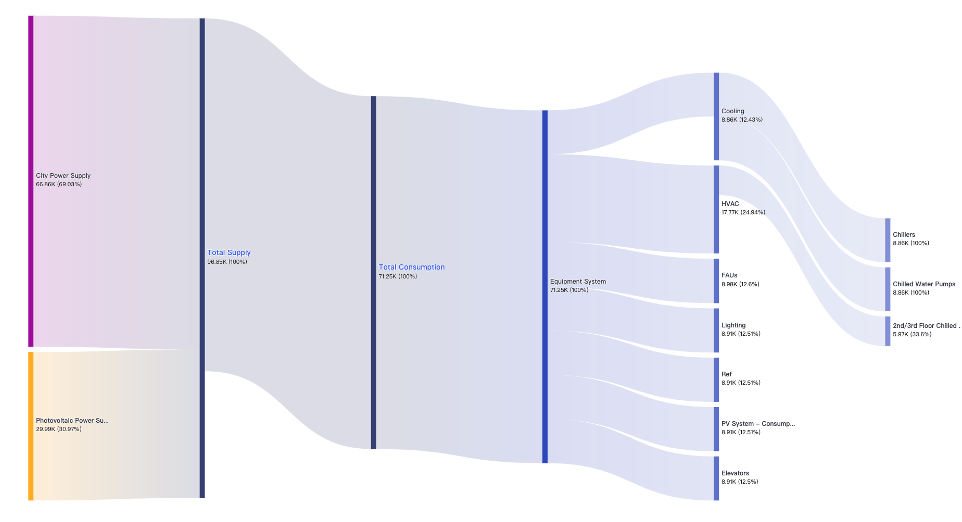

Akila’s new feature not only streamlines maintenance tasks but also provides a comprehensive view of the entire equipment lifecycle, from installation to ongoing maintenance. Continuous monitoring and real-time data give teams the ability to monitor equipment performance closely, ensuring that anomalies are detected and addressed as quickly as possible.

With these insights, maintenance teams can keep an eye on the performance of every single equipment, ensuring that any anomaly will be detected and address in the quicker possible way and prioritize daily work more effectively.

Not only can this feature help the maintenance teams to keep assets in the best condition, but Akila also gives them the tools to manage efficiently their work. Indeed, it provides powerful insights into equipment such as recurring issues helping the teams with decision-making. That way, maintenance teams can plan preventative tasks and inspections, but also prioritize their day-to-day work according to the emergency occurring as they are now aware with the help of alerts.

Akila’s platform also allows them to track the progress of their work order, and coordinate when necessary so the maintenance teams stay ahead of potential problems, preventing disruptions.

This system-wide visibility enhances operational efficiency, helps allocate resources more effectively, and contributes to smoother, more reliable performance.

By linking real-time monitoring and actionable maintenance task, Akila significantly improves preventative maintenance. With this new feature, maintenance teams will now be able to respond swiflty to issues by creating work orders more rapidly as they will now be connected to alarms. As a result, maintenance teams to be more efficient and prevent minor issues from turning into huge breakdowns.

Akila’s platform and its tools are becoming essential as it allows for effective asset management. Its real-time insights give unprecedented control to property managers over their assets, enabling them to detect issues quicker than ever. Akila helps organizations work at their best while protecting their equipment and resources for the future. As the landscape of asset management evolves, integrating such cutting-edge technology will be vital for businesses striving to maintain peak efficiency and ensure long-term operational excellence.